In earlier times, a typical laboratory procedure consisted of separating the precipitate from the supernatant solution by filtering the mixture. Pouring the solution carefully over a glass rod that was tilted and held against folded filter paper that was fixed inside a glass funnel was all that was required to carry out the operation, which was very straightforward and easy to do. However, the procedure required a significant amount of time and consumed valuable time in the laboratory.

The use of a high speed centrifuge in laboratories is now as commonplace as the use of a hot plate, pH meter, or thermometer. Today, a centrifuge is an accepted laboratory commodity. The ability to rapidly separate the precipitate from the supernatant liquid is made possible by this method, which utilizes the centrifugal force principle as the foundation for its separation power. When the solution is spun in a circular motion at high speeds, the centrifugal force causes particles that are suspended in the solution to collect at the base of the low speed centrifuge tube. The centrifuge is stopped after a predetermined amount of time, and the supernatant liquid is collected separately. The ability to rapidly separate the precipitate in more than one tube is the most significant advantage.

The centrifuge can save a significant amount of time, but if it is used carelessly, it can cause damage to the system as well as injuries to you and any other people who may be in the laboratory at the time.

Potential Hazards

To begin, the following is a rundown of the potential dangers that could arise from the utilization of a centrifuge:

Higher speeds of operation increase the risk of tube breaking.

The contents of the tubes leak out, potentially causing damage to the bowls and other components found inside the tubes.

Aerosols of dangerous or corrosive liquids could be released into the laboratory environment There is a risk of flying debris from broken tubes

The potential for contamination due to the escape of materials that are biologically active or radioactive

A Reduction in the Number of Operational Risks

Safety should be your number one priority in the laboratory just as it is in any other operation

Wear your lab coat, and also make sure to protect your eyes by donning a pair of safety glasses

When centrifuging corrosive, biohazardous, or radioactive materials, it is strongly advised that a face shield be worn at all times

A face shield will provide additional defense against things that are falling from the sky

Ahead of Time Inspection

When the system is used for the first time, taking a few minutes to perform an initial inspection before doing so can prevent a significant number of issues:

Make sure that the bowls and tubes of the centrifuge are clean and free of any spillages or debris from broken tubes.

Examine the tubes that make up the centrifuge. When being centrifuged, these should be free of any cracks and come equipped with sealing caps to prevent any leaks from occurring.

The rotor has been appropriately positioned, and it is securely fastened to the central drive hub.

Attention During the Procedure

Centrifuge tubes made of unbreakable plastic should preferably be used.

It is important to avoid overfilling the tubes because doing so can lead to leaks while the experiment is being run. During high-speed runs, the upward movement of the solution along the tube walls may be caused by centrifugal force.

Before beginning the run, check to see that the filled tubes are positioned appropriately in the buckets.

Before beginning the centrifugation process, the opposite tube pairs need to have their weights adjusted so that they are properly balanced.

Run speeds should never exceed those recommended by the manufacturer.

Before beginning, ensure that the tubes are properly sealed. The use of aluminum foil as a covering is not very helpful because it is prone to tearing or flying off during the process.

Before using the system, the top cover must always be securely fastened.

Before opening the top cover, you should wait until the centrifuge has reached equilibrium. In the event that potentially dangerous materials are being worked with, you should wait at least ten to fifteen minutes before opening the cover.

When the centrifuge is in operation, you should not make any attempts to move its position.

Maintain a spill kit close at hand in order to respond appropriately to any accidents that may occur.

When opening centrifuge tubes that contain potentially hazardous biomaterials, always do so inside of a biosafety cabinet.

Care Following an Operation

It is just as important to perform a post-operation inspection before exiting the high speed refrigerated centrifuge as it is to perform a pre-operation inspection.

When using the centrifuge, it is necessary to make the required entries in the user log book.

After the allotted time has passed, carefully open the centrifuge, and check to make sure there are no leaks inside.

In the event of any small spills on the interior, wipe them up with a gentle detergent and a soft brush, then rinse with deionized water, and finally pat them dry with clean tissue.

Inspect the rotor and wells for any signs of damage, and if you find any, report it to the lab in charge so that it can be fixed or replaced as soon as possible.

In conclusion, we can say that a is a helpful piece of laboratory equipment; however, when it is being used, it is imperative to follow all of the necessary safety guidelines.

The pre-analytical processing of human samples like blood, urine, or sputum typically takes place in a clinical laboratory centrifuge. In reference procedures for the measurement of lipoproteins, the instrument can also be used to separate cellular components and DNA fragments from one another. Additionally, the instrument can be used to separate lipoproteins.

Modern centrifuges are available in a wide range of configurations, each of which integrates various forms of cutting-edge technology. Selecting the appropriate alternative is absolutely necessary for effective centrifugation. However, if you don't have a good idea about the options that are available to you, this can be a complicated process. Therefore, it is imperative that laboratory professionals educate themselves about the numerous available choices before they go about the process of actually purchasing the device.

Your centrifugation needs, the amount of space you have available, the type of model you want (benchtop or floor standing), and your budget are all important considerations to make before making a purchase decision. Benchtop centrifuges are not only a practical and space-saving solution for smaller and medium-sized laboratories, but they are also an efficient and cost-effective solution. The most up-to-date hardware comes pre-loaded with adaptable features and can run on a wide range of operating systems, each of which is optimized for a specific set of software requirements. There are high-speed benchtops, micro centrifuges, small clinical centrifuges, and general-purpose benchtops available. There are also small clinical centrifuges. On the other hand, floor models are ideal for high-capacity sample processing because of their larger capacities. There are three types of centrifuges that fall under the floor-model category: super-speed centrifuges, ultracentrifuges, and low-speed centrifuges.

The fundamental configuration of a laboratory centrifuge is quite straightforward and consists of a closed chamber housing a rotor that rotates at high speed within the chamber. When selecting an apparatus, some factors to take into consideration are as follows:

The maximum acceleration that the device is capable of producing

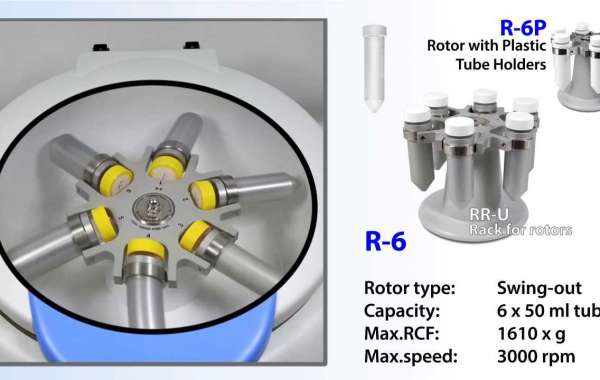

There are two types of rotors available to support your application: swinging buckets and fixed angles.

When compared to the centrifuges of other companies, both the speed and capacity of ours are superior.

Specifications pertaining to security and technology

Ergonomics

Obtainability of supplementary items and replacement components

In a given run, shift, or day, the number of tubes or samples that will be processed

Durability as well as the terms of the warranty

Costs associated with operation, maintenance, and initial setup

A lid lock, a clear lid for observing samples, a Cool-Flow air flow design, and automatic rotor imbalance detection are all essential safety features to look for in a centrifuge. In addition to this, it is essential that the personnel in the laboratory are properly trained to use the equipment in a secure manner. Here are some tips:

Never take safety features for granted because they are there to keep you safe.

It is imperative that you remain inside the centrifuge until the maximum speed has been reached.

In the event that the power goes out, do not open the lid for at least an hour in order to retrieve the samples.

Last but not least, there are a number of benefits that come along with purchasing the centrifuge from a reputable provider of laboratory equipment. In addition to having a wide selection of models from which to choose, laboratories would also be guaranteed to receive excellent maintenance service support.