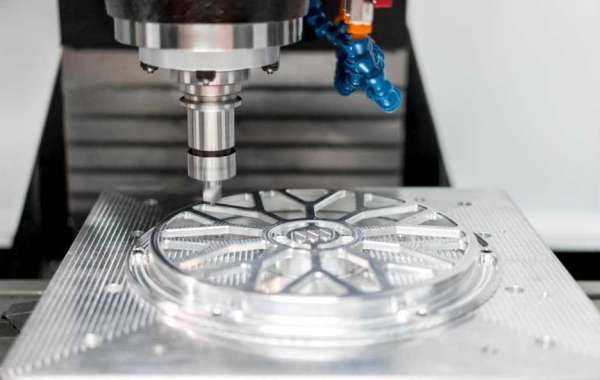

Rapid Tooling plays a crucial role in CNC Machining by accelerating the production process while maintaining high precision and quality. It bridges the gap between prototype development and full-scale manufacturing, enabling manufacturers to reduce lead times and meet market demands efficiently. Here are the key aspects highlighting its role in CNC Machining:

1. Faster Prototyping and Product Development

Rapid Tooling facilitates quick prototyping by producing molds and tools at a much faster rate compared to traditional methods. It allows manufacturers to create functional prototypes for testing and validation, reducing the time needed to bring new products to market.

2. Reduced Production Lead Time

With Rapid Tooling, CNC Machining processes become more streamlined. Custom tools and molds are created quickly, enabling manufacturers to start production sooner. This reduced lead time is critical for industries operating under tight production schedules.

3. Cost-Effective Manufacturing

Rapid Tooling lowers production costs by minimizing the need for expensive tooling setups. Since it supports short-run production and small-batch manufacturing, companies can test and refine designs without committing to large-scale production investments.

4. Improved Design Flexibility

Rapid Tooling allows for quick design modifications, making it easier to adapt to changing project requirements. CNC Machining can incorporate updated designs seamlessly, ensuring that manufacturers stay responsive to customer demands and market trends.

5. Enhanced Product Quality and Consistency

By using precise tools created through Rapid Tooling, CNC Machining achieves consistent product quality across production batches. This consistency ensures that all components meet exact specifications, reducing the risk of defects and improving overall reliability.

Rapid Tooling has become an essential element in CNC Machining, enabling manufacturers to produce components faster, reduce costs, and maintain product quality. Its integration into the production process drives innovation and competitiveness in today’s fast-paced industrial landscape.