In today's rapidly evolving industrial landscape, energy efficiency has become a top priority for businesses across various sectors. Among the many technologies available, brazed plate heat exchangers (BPHEs) have emerged as a key solution for enhancing energy efficiency. This article explores the significant role of BPHEs in improving energy efficiency and highlights their advantages in various applications.

Understanding Brazed Plate Heat Exchangers

1.1 How https://www.yojointernational.com/Brazed-Plate-Heat-Exchanger/Brazed-Plate-Heat-Exchanger-ZL200A.shtml Work:

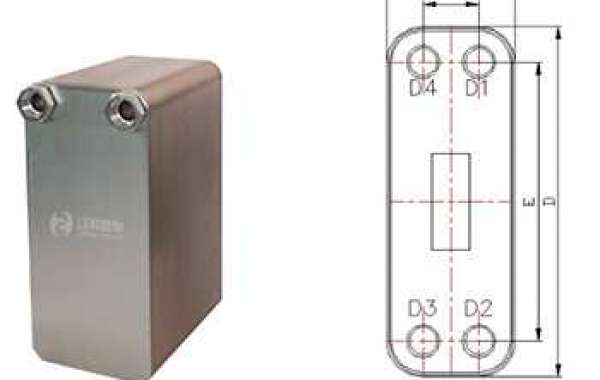

- The compact design of BPHEs consists of multiple plates stacked together and brazed at their contact points.

- Fluids flow through the alternating channels formed by the plates, allowing for efficient heat transfer.

1.2 Advantages of Brazed Plate Heat Exchangers:

- High thermal conductivity enables efficient heat transfer, resulting in reduced energy consumption.

- Compact size allows for space-saving installations, making them ideal for applications with limited space.

- Robust construction and easy maintenance contribute to their long lifespan and reliability.

Enhancing Energy Efficiency with Brazed Plate Heat Exchangers

2.1 Industrial Applications of Brazed Plate Heat Exchangers:

- Heating Systems: BPHEs are commonly used in district heating, HVAC systems, and industrial heating processes, reducing energy consumption and costs.

- Cooling Systems: BPHEs enable efficient heat removal in refrigeration systems, resulting in energy savings and enhanced cooling performance.

- Waste Heat Recovery: BPHEs capture and utilize waste heat from various industrial processes, improving overall energy efficiency.

2.2 Renewable Energy Systems:

- BPHEs play a vital role in renewable energy systems, such as solar thermal and geothermal systems, by efficiently transferring heat between the energy source and the end-use applications.

- They contribute to reducing reliance on traditional energy sources and lowering carbon emissions.

Considerations and Customization About Brazed Plate Heat Exchangers

3.1 Fluid Compatibility:

- Brazed Plate Heat Exchangers can be designed using different materials to ensure compatibility with various fluids, including corrosive or high-temperature media.

3.2 Performance Optimization:

- Tailored designs and plate patterns can be employed to maximize heat transfer efficiency, taking into account specific application requirements.

3.3 Integration and System Design:

- https://www.yojointernational.com/news/Brazed-Plate-Heat-Exchanger-Model-ZL200A-Compare.shtml can be integrated into existing systems or designed as part of a new system, enabling seamless integration and optimal energy performance.

Maintenance and Lifespan About Brazed Plate Heat Exchangers

4.1 Regular Inspections:

- Periodic inspections are crucial to identify potential issues, such as fouling or leaks, which may hinder the heat exchanger's performance.

4.2 Cleaning Procedures:

- Cleaning protocols, including chemical or mechanical methods, should be implemented to remove deposits and maintain optimal heat transfer efficiency.

4.3 Lifespan and Replacement:

- With proper maintenance, BPHEs can have a long lifespan. However, if replacement becomes necessary, it is important to consider updated designs to achieve higher efficiency and energy savings.

Conclusion

Brazed plate heat exchangers offer a multitude of advantages for improving energy efficiency across various industries. Their compact design, high thermal conductivity, and versatility make them an ideal choice for heating, cooling, and waste heat recovery applications. By utilizing BPHEs, businesses can significantly reduce energy consumption, lower operating costs, and contribute to a more sustainable future.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.

Welcome to contact us if you need to know more about brazed heat exchanger details or order wholesale.

Email:zy@jsyuanzhuo.com