effective thermal management has become a critical factor in ensuring the longevity and performance of devices. Custom Thermal Solutions play a crucial role in managing heat, enhancing efficiency, and preventing overheating of electronic components. As electronics become smaller, more powerful, and more complex, the need for tailored thermal solutions has grown. This article explores the significance of Custom Thermal Solutions in electronics and why they are essential for modern devices.

1. Optimizing Heat Management

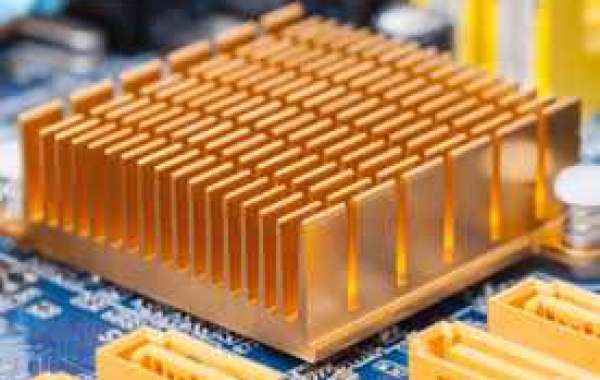

The primary function of Custom Thermal Solutions in electronics is to manage heat effectively. Electronics generate significant amounts of heat during operation, which, if not properly dissipated, can damage internal components, reduce performance, and shorten the lifespan of devices. Custom solutions, such as heat sinks, thermal pads, and liquid cooling systems, are designed to meet the specific thermal demands of each device. By using materials that provide optimal thermal conductivity, these solutions ensure that heat is efficiently transferred away from sensitive components.

2. Improving Device Performance

Thermal management is directly tied to the performance of electronic devices. High temperatures can cause components to throttle, reducing processing speeds and leading to inefficient operation. Custom Thermal Solutions are designed to maintain optimal operating temperatures, allowing devices to perform at their best. With better heat dissipation, devices can run faster and more efficiently, which is especially important in applications such as computing, gaming, telecommunications, and industrial machinery.

3. Ensuring Longevity and Reliability

Overheating can cause irreversible damage to electronic components, including circuit boards, semiconductors, and processors. By implementing Custom Thermal Solutions, manufacturers can extend the lifespan of their products. These solutions help prevent thermal stress, which can lead to component failure and reduce the need for frequent repairs or replacements. A well-designed thermal management system increases the overall reliability of electronics, which is vital in sectors like medical devices, automotive electronics, and aerospace.

4. Energy Efficiency

Effective thermal management not only prevents overheating but also contributes to energy efficiency. Custom Thermal Solutions can reduce the need for high-powered cooling systems, which can consume large amounts of energy. By improving heat dissipation and optimizing airflow, these solutions help minimize energy consumption, making electronics more sustainable and cost-effective to operate. This is particularly important in the context of green energy and environmentally conscious design practices.

5. Tailored to Specific Applications

One of the key advantages of Custom Thermal Solutions is their ability to be tailored to the unique needs of different electronic applications. Whether it's for compact smartphones, high-performance computing systems, or large industrial machines, custom solutions can be designed to fit the specific thermal challenges of each device. This customization ensures maximum efficiency and performance, addressing unique heat dissipation requirements for each product.

In the electronics industry, Custom Thermal Solutions are indispensable for managing heat, improving performance, enhancing reliability, and ensuring energy efficiency. As devices continue to evolve, the demand for tailored thermal solutions will only increase. By investing in custom solutions, manufacturers can not only protect their products from heat damage but also optimize their overall functionality and lifespan.