Once there is not an alignment of the coils, it will cause errors in the subsequent steps and the material wasting or the downtime of the machine. Therefore, when processing the web, the web guiding is necessary for the offset and it is widely used in a bonding machine, a printing machine, a coater, a paper machine, a dyeing machine, etc, which has various requirements for the winding and rewinding processes. An all-in-one web guiding system refers to the technical operation of the coils to keep the edge of the coil neat and consistent during spraying, printing, die-cutting, lamination, slitting, or other coil winding processes. Its wide applications have brought huge benefits to the coil industries. The all-in-one system has automated industries such as corrugated paper, textile, printing, labels, papermaking, plastic film, building materials, tires, and non-woven corrugated paper processing.

The Work Principle Of All-in-one Web Guiding System

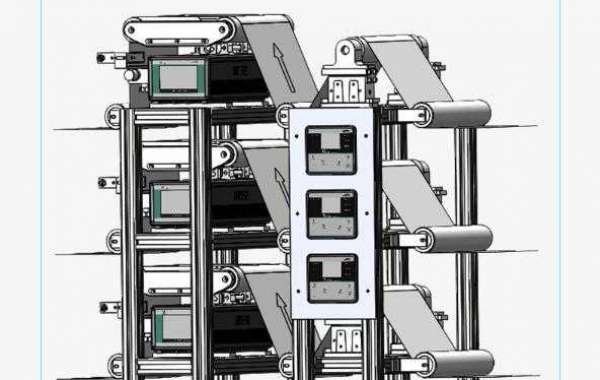

The high-precision, high-speed, and high-efficiency coil automatic processing has high requirements for the lateral position of the controlled coil. Equipped with a high-performance automatic web guide system is the key to improving coil production capacity and output. The coil will shift laterally during moving, unwinding and rewinding. Therefore, the web guiding system can be installed in the above three positions for controlling the coil to pass through the designated position accurately.

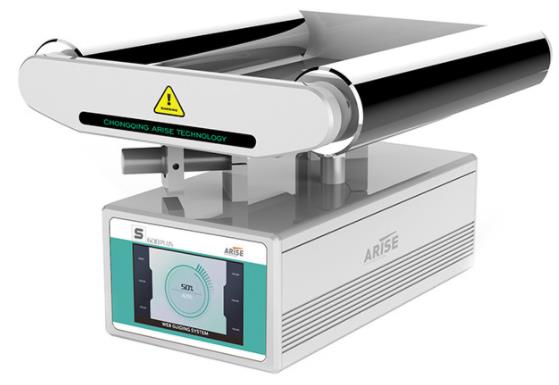

All-in-one web guide machine adopts high-speed microprocessor, digital, modular and intelligent circuit design. The advanced programming, user-friendly interface, high-performance components and complete circuit protection design, make the system run continuously and stably. The response time of the control system is less than 0.01 seconds and the accuracy of the system itself can reach 0.01mm. During the coil winding process, the web guide sensor detects the position of the edge or line to pick up the deviation signal of the edge or line position.

Then the position deviation signal of the web guiding machine is sent to the web guide controller for logical operation. After the judges and processes of the control unit, it will control the drive motor to skew the web to the correct position.

The Functions Advantages Of All-in-one Web Guiding System

The high-performance web guide system has a fast response time, high-speed CPU calculation and can support ultrasonic sensors, photoelectric sensors, CCD sensors for the different response of coils. It has the advantages of simple and practical operation, ball screw, high precision, low noise, maintenance-free, long service life, flexible installation.

Center compensation deviation web guiding can quickly guide the high-frequency feed errors. It integrates operation and control technology with a highly compact web guide. The guiding system has an innovative sensor detection real-time display and a real-time feedback system for system detection information.

The all-in-one system is driven by a brushless DC servo motor and precision ball screw, with compact structure, good mechanical rigidity, low inertia, high precision, suitable for high-speed and high-precision web guide in coil processing.

Three Detection Methods Provided By All-in-one Web Guiding System

The All-in-one web guiding system provides three different detection methods, which include edge detection, line tracking, or alignment detection. The drive system is driven by a brushless motor and the drive stroke is strictly proportional to the coil offset. The system can also be used in conjunction with different sensors to meet the needs of different coils, such as ultrasonic sensors, photoelectric sensors, CCD sensors, etc. The microcomputer digital controller provides precise control for the various functions of the guide system.

Daily Maintenance Of All-in-one Web Guiding System

1.Alignment: Tools, workpieces and accessories should be placed neatly. The web guiding system should be equipped with thorough protection equipment.

2. Cleaning: Cleaning inside and outside including all sliding surfaces, guidelines, gears, racks, etc, ensuring all parts will not leak oil, water, air, or electricity.

3. Lubricating: Refuel and change oil timely. The oil quality meets the requirements. Oil tanks, oil guns, oil cups, lumps, tubes should clean and keep complete.

4.Safety: The operation personnel should be familiar with the maintenance structure of the web guide system, complying with the operating procedures and reasonably use the all-in-one system with daily maintenance, carefully maintenance tools to prevent accidents.

For more information, please visit the page of why choose all-in-one web guide system.