Choosing the right PET Preform Mold is critical to the success of your PET bottle production. Here are some factors to consider when choosing a PET preform mold:

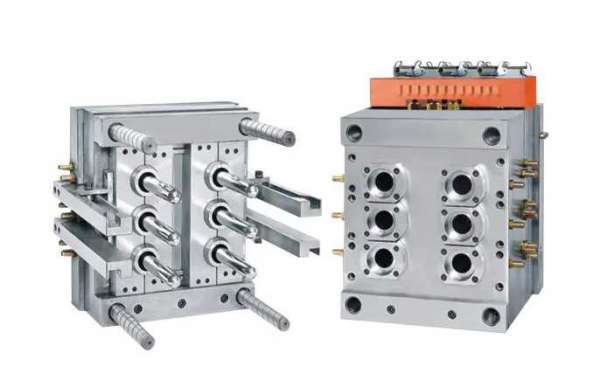

Mold Design: Choose a mold design that is optimized for your PET bottle shape and size. The mold design should ensure proper gate location, wall thickness, and material flow to achieve consistent quality of preforms.

Mold Material: Choose a mold material that can withstand high temperatures and pressures, as well as resist wear and tear from continuous use. High-quality mold materials such as H13, S136, or 2316 stainless steel can provide longer mold life and better performance.

Mold Cooling: Proper cooling of the mold is essential to achieve consistent cycle times and preform quality. Consider the cooling channel design and location to ensure uniform cooling throughout the mold.

Mold Manufacturer: Choose a reputable mold manufacturer with experience in PET preform molds. A reliable manufacturer can provide technical support, spare parts, and maintenance services to ensure the long-term performance of the mold.

Mold Cost: The cost of the mold is an important consideration. However, the cheapest option may not always be the best choice. Consider the overall value of the mold, including its performance, reliability, and maintenance requirements, to make an informed decision.

Mold Maintenance: Proper maintenance of the mold is essential to ensure its longevity and consistent quality of preforms. Consider the ease of maintenance, availability of spare parts, and support from the manufacturer.

Mold Testing: Before purchasing a mold, conduct a thorough mold testing to evaluate its performance and quality of preforms produced. This will help you make an informed decision and avoid costly mistakes.

By considering these factors, you can choose a PET preform mold that is optimized for your bottle production needs and provides reliable, consistent, and high-quality preforms. Master Packing Co.,Ltd Plast has earned an excellent reputations for high quality Bottle Machine , reliability through machines best performance. The key to our success comes from innovative design, quality machine performance, considerate after sales services. Due to the support of our experienced techno-commercial personnel, our customers place complete trust reliance on Bottle Machine Manufacturer Master Packing Co.,Ltd Machinery. Click https://www.master-machinery.com/product/injection-machine/ to know more information.